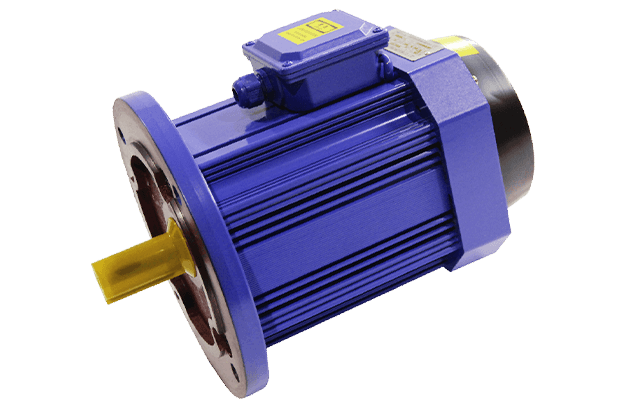

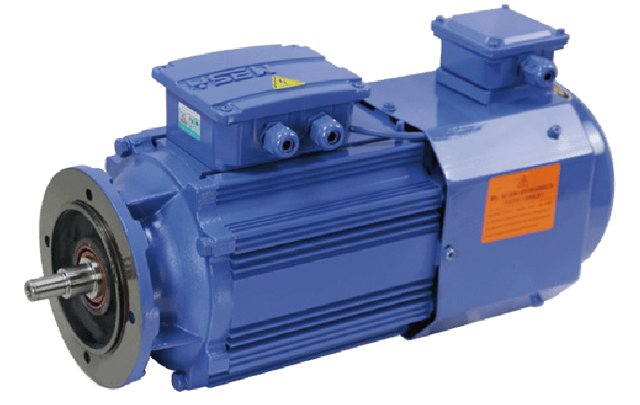

Mótar Tosaigh Bog Rotor Soladach Sraith YSE (R1)

Cur síos ar an Táirge

Tá tréithe meicniúla réasúnta bog ag mótair YSE, is é sin, an chasmhóimint stalla mór, duillín mór, agus luasghéarú mall.Dá bhrí sin, is féidir an craein a bheith feistithe le mótar YSE chun éifeacht tosaithe mall a fháil, ionas gur féidir an feiniméan tionchair a fheabhsú go mór nuair a thosaíonn an craein.(Is féidir leis an mótarfheithicil rótar créachta a athsholáthar, rud a fhágann go gcuirfear deireadh leis an ngá atá le friotóirí seachtracha agus comhpháirteanna rialaithe leictreonacha cosúil le rialtóirí cam, costais a shábháil, teipeanna a laghdú, agus iontaofacht a fheabhsú)

Tá sruth beag rotor faoi ghlas ag an tsraith mhótair seo, ar féidir leis freastal ar riachtanais tosaithe agus bogshodar na craein go minic.Ní bheidh an foirceannadh mótair sruthán amach ar feadh 6-7 nóiméad tar éis an mótar a bheith faoi ghlas.Tá sé feistithe le coscán AC eitleáin, agus is féidir an chasmhóimint coscánaithe a choigeartú go treallach.Stopann an craein Is féidir oibriú stad mall a fháil nuair nach bhfuil aon tionchar ann.

Ceithre bhuntáiste / gnéithe den scoth de shraith YSE:

Tús bog Ag siúl gan tionchar.

Is féidir le fórsa tosaigh mór oibriú go leanúnach ar feadh 8 uair an chloig.

Meáchan éadrom agus coigilte fuinnimh 1/4 reatha coigilt fuinnimh agus cosaint an chomhshaoil.

Praiticiúlacht láidir Cuir in oiriúint d'oibríocht timpeallachta ardteochta.

Struchtúr agus Prionsabal

Is mótar coscáin caillteanas cumhachta é an mótar coscáin tosaithe bog sraith YSE (3ú giniúint), agus tá a choscán diosca DC suiteáilte ar chlúdach deiridh deireadh síneadh neamh-aiseach an mhótair.Is é an prionsabal oibre ná nuair a bhíonn an mótar ceangailte leis an soláthar cumhachta, go bhfuil ceartaitheoir an choscáin ceangailte freisin leis an soláthar cumhachta mar gheall ar an mhealladh leictreamaighnéadach.Meallann an leictreamaighnéad an armature agus comhbhrú an earraigh, rud a fhágann go bhfuil an diosca coscáin ag scaradh ón armature agus an clúdach deiridh, rud a fhágann go n-oibríonn an mótar.Nuair a ghearrtar an chumhacht, cailleann an leictreamaighnéad coscáin mhealladh leictreamaighnéadach, agus brúnn fórsa an earraigh an armature chun an diosca coscáin a chomhbhrú.Faoi ghníomhaíocht an chasmhóiminte frithchuimilte, stopann an mótar rothlú láithreach.

Paraiméadair coscáin AC rótar soladach mótair tosaithe bog den chéad ghlúin (R1).

| Suíochán Uimh. | Cumhacht | Voltas | Minicíocht | córas oibre | Leibhéal cosanta | Insliúleibhéal |

| 80~160 | 0.4~15KW | 380v | 50HZ | S3 40% | IP54 | F |

Paraiméadair theicniúla sraith YSE

| Cineál | Cumhacht(D.KW) | Casmhóiminte a Bhac(DN·M) | Ag bacadhReatha(D·A) | Luas rátáilte(r/nóim) | Luas sioncrónach(r/nóim) | Casmhóiminte coscáin(BK- N·M) | |

| 4-leibhéal | 801-4 | 0.4 | 4 | 2.8 | 1200 | 1500 | 1-6 |

| 802-4 | 0.8 | 8 | 3.6 | 1-6 | |||

| 90S-4 | 1.1 | 12 | 6.2 | 1-6 | |||

| 90L-4 | 1.5 | 16 | 7.5 | 2-10 | |||

| 100L1-4 | 2.2 | 24 | 10 | 2-10 | |||

| 100L2-4 | 3 | 30 | 12 | 3-20 | |||

| 112M-4 | 4 | 40 | 17 | 3-30 | |||

| 132S-4 | 5.5 | 52 | 24 | 3-30 | |||

| 132M-4 | 7.5 | 76 | 32 | 10-40 | |||

| 160M-4 | 11 | 116 | 58 | 10-40 | |||

| 160L-4 | 15 | 150 | 75 | 20-50 | |||

| 180M-4 | 18.5 | 185 | 92 | 20-50 | |||

| 180L-4 | 22 | 220 | 110 | 20-60 | |||

| 200L-4 | 30 | 300 | 170 | 20-60 | |||

| 225S-4 | 37 | 370 | 190 | 20-60 | |||

| 225M-4 | 45 | 450 | 248 | 30-80 | |||

| 250-4 | 55 | 550 | 380 | 30-80 | |||

| 280-4 | 75 | 750 | 430 | 75-250 | |||

| 280-4 | 90 | 900 | 510 | 75-250 | |||

| 315-4 | 110 | 1100 | 600 | 150-450 | |||

| 315-4 | 132 | 132 | 780 | 150-450 | |||

| 315-4 | 160 | 1600 | 940 | 150-450 | |||

| 315-4 | 200 | 2000 | 1200 | 150-450 | |||

| 6-leibhéal | 80M2-6 | 0.4 | 8 | 4 | 800 | 1000 | 2-10 |

| 90S-6 | 0.8 | 12 | 5 | 2-10 | |||

| 90L-6 | 1.1 | 23 | 8 | 3-20 | |||

| 100L-6 | 1.5 | 33 | 11.5 | 3-20 | |||

| 112M-6 | 2.2 | 46 | 16 | 3-30 | |||

| 132S-6 | 3 | 60 | 19 | 10-40 | |||

| 132M1-6 | 4 | 82 | 25 | 10-40 | |||

| 132M2-6 | 5.5 | 112 | 42.5 | 10-40 | |||

| 160M-6 | 7.5 | 160 | 52 | 20-50 | |||

| 160L-6 | 11 | 235 | 64 | 20-50 | |||

| 180L-6 | 15 | 270 | 88 | 20-60 | |||

| 200L1-6 | 18.5 | 320 | 110 | 30-70 | |||

| 200L2-6 | 22 | 435 | 150 | 30-70 | |||

| 225M-6 | 30 | 540 | 180 | 30-80 | |||

| 250-6 | 37 | 660 | 220 | 30-80 | |||

| 280-6 | 45 | 810 | 270 | 75-250 | |||

| 280-6 | 55 | 990 | 330 | 75-250 | |||

| 315-6 | 75 | 1350 | 450 | 150-450 | |||

| 315-6 | 90 | 1620 | 540 | 150-450 | |||

| 315-6 | 110 | 1980 | 650 | 150-450 | |||

| 315-6 | 132 | 2300 | 795 | 150-450 | |||

| 8-leibhéal | 80M-8 | 0.4 | 8 | 3.7 | 600 | 750 | 1-6 |

| 90M-8 | 0.8 | 16 | 6 | 1-6 | |||

| 90L-8 | 1.1 | 22 | 8.5 | 2-10 | |||

| 100M-8 | 1.5 | 32 | 11 | 3-30 | |||

| 112S-8 | 2.2 | 48 | 14.8 | 3-30 | |||

| 132M-8 | 3 | 60 | 18 | 10-40 | |||

| 160M1-8 | 4 | 80 | 23 | 10-40 | |||

| 160M2-8 | 5.5 | 100 | 27 | 20-50 | |||

| 160L-8 | 7.5 | 150 | 36 | 20-50 | |||

| 180L-8 | 11 | 220 | 53 | 20-60 | |||

| 200L-8 | 15 | 300 | 70 | 30-70 | |||

| 225S-8 | 18.5 | 370 | 88 | 30-80 | |||

| 225M-8 | 22 | 450 | 110 | 30-80 | |||

| 250-8 | 30 | 600 | 160 | 75-250 | |||

| 280-8 | 37 | 740 | 200 | 75-250 | |||

| 280-8 | 45 | 900 | 244 | 75-250 | |||

| 315-8 | 55 | 1100 | 300 | 150-450 | |||

| 315-8 | 75 | 1500 | 410 | 150-450 | |||

| 315-8 | 90 | 1800 | 490 | 150-450 | |||

| 315-8 | 110 | 220 | 600 | 150-450 | |||

| 10-leibhéal | 90L-10 | 0.4 | 11 | 3.2 | 480 | 600 | 2-10 |

| 100L-10 | 0.8 | 17 | 5.2 | 3-20 | |||

| 112M-10 | 1.5 | 40 | 10.8 | 3-20 | |||

| 132S-10 | 2.2 | 60 | 15 | 10-40 | |||

| 132M-10 | 3 | 80 | 17.5 | 10-40 | |||

| 160M1-10 | 4 | 110 | 22 | 20-50 | |||

| 160M2-10 | 5.5 | 150 | 29 | 20-50 | |||

| 160L-10 | 7.5 | 210 | 40 | 20-50 | |||

| 180M-10 | 11 | 300 | 55 | 20-60 | |||

| 180L-10 | 15 | 410 | 70 | 20-60 | |||

| 200L1-10 | 18.5 | 500 | 92 | 30-70 | |||

| 200L2-10 | 22 | 600 | 110 | 30-70 | |||

| 225M-10 | 30 | 820 | 148 | 30-80 | |||

| 12-leibhéal | 90L-12 | 0.4 | 6 | 3.5 | 400 | 500 | 2-10 |

| 100L-12 | 0.8 | 15 | 4 | 3-20 | |||

| 112M-12 | 1.5 | 37 | 9.6 | 3-20 | |||

| 132M-12 | 3 | 76 | 15.5 | 10-40 | |||

| 160L-12 | 5.5 | 148 | 34.5 | 20-50 | |||

| 180M-12 | 7.5 | 202 | 38 | 20-60 | |||

| 180L-12 | 11 | 285 | 47 | 20-60 | |||

| 200L1-12 | 15 | 376 | 60 | 30-70 | |||

| 225S-12 | 18.5 | 467 | 74 | 30-70 | |||

| 22MS-12 | 22 | 562 | 90 | 30-80 | |||

| 225M-12 | 30 | 760 | 130 | 30-80 | |||

| 16-leibhéal | 180M-16 | 3 | 98 | 32 | 300 | 375 | 20-60 |

| 180L-16 | 4 | 116 | 37 | 20-60 | |||

| 200L-16 | 4 | 116 | 37 | 20-60 | |||

| 225S-16 | 7.5 | 260 | 80 | 30-80 | |||

| 225S-16 | 11 | 390 | 110 | 30-80 | |||